Calcite (CaCO3)

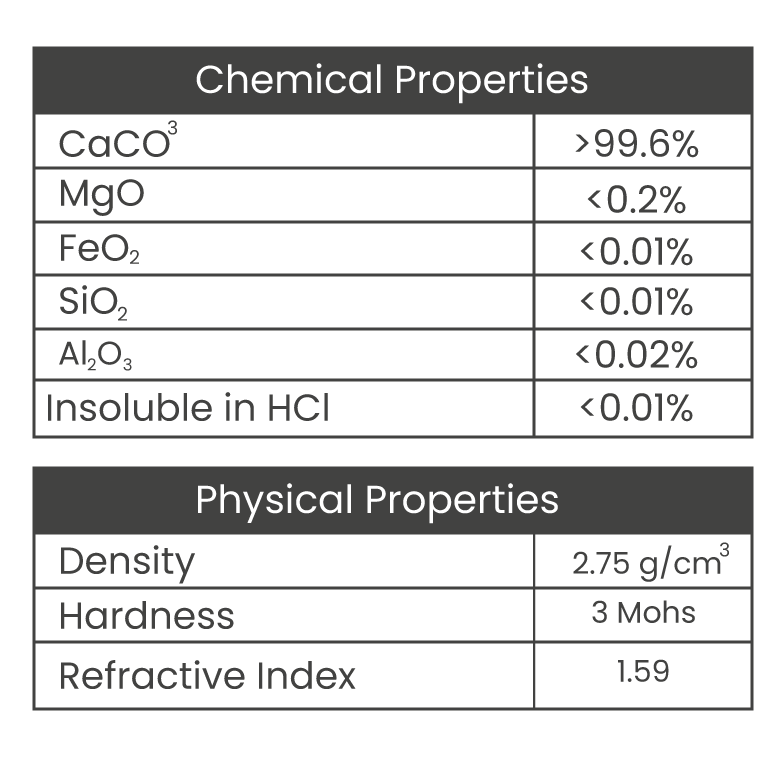

With its chemical formula CaCO3, it is an industrial mineral which forms the carbonated rock, and which could be easily grinded with its high purity and whiteness. It is crystallized in a hexagonal system, the density of calcite is 2.75 g/cm3 and its hardness is 3 Mohs according to Mohs scale. Calcite's melting point is 1339 Celsius Degree. It foams by reacting with diluted HCl. The pure crystal contains 56% calcium oxide (CaO) and 44% Carbon Dioxide (CO2) .

Properties

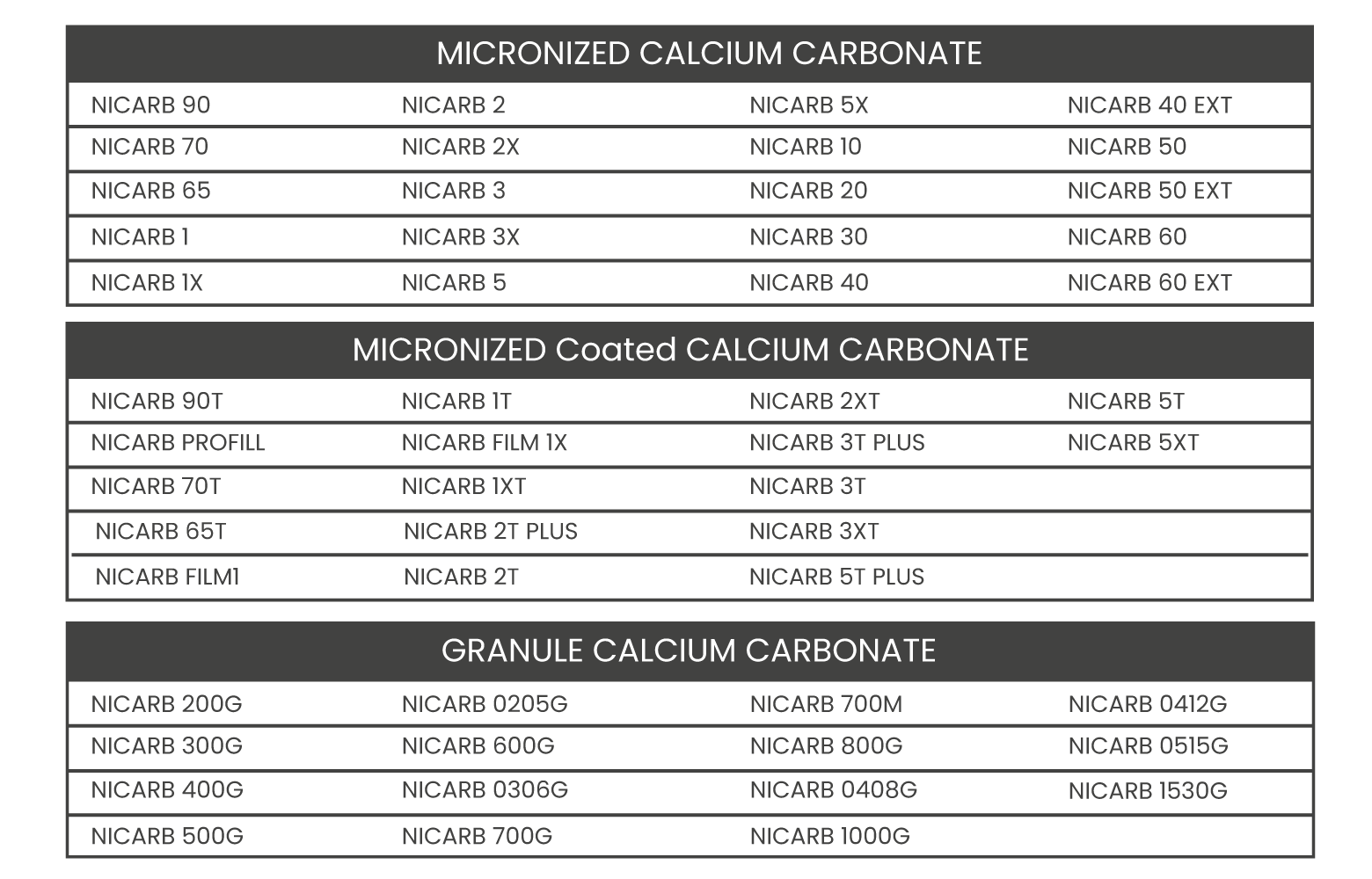

Calcite Products

Usage Areas

Paint Industry

Calcite is the most important filler used in paint production.

•Thanks to its high whiteness and purity, it provides optimum hiding power and opacity.

•It is an ideal filling material in undercoat paints thanks to its low oil absorption.

•It is efficient in paint adherence with its reinforcing features.

•It increases the shock resistance of the paint film.

•Thanks to its high purity and whiteness, it reduces TiO2 usage, optimizing the product cost.

•It also optimizes the product cost by enabling the thickening and increasing the volume of the paint.

•Thanks to its high brightness, it positively effects the brightness levels on dust paint.

Cable Industry

Calcite has great connectivity with the plastic agents used in cable production. Thanks to this feature, it is used as a filling material in the production of interior filling, outer shell and cable channels. Both coated and uncoated calcite could be used, based on the preference of the manufacturer.

• As calcite is a filling material, it optimizes the production costs by reducing the usage of plastic agents such as PVC. PE etc.

• It reduces the bleaching inputs of the manufacturer thanks to its whiteness.

• Does not contain heavy metals.

• Protects the manufacturing hardware against wear.

• As calcite is non-combustible, it has great importance for the sector.

• When used in the outer shell of the cables, calcite increases its shock resistance.

• More higher quality surface smoothness is obtained when coated calcite is used.

Plastic Industry

Calcite is an important filling material in the production of plastic from materials such as PE

(Polyethylene), PVC (Polyvinyl chloride) and PP (Polypropylene). As it possesses features such as;

durability, hardness, flexibility, prevention of internal strain and resistance against high

temperatures, it is used in manufacturing sectors such as rubber, PVC pipes, PVC pipe connections,

hose, cables, PVC frame, wainscot, PVC compound, masterbatch, footbed etc, with plastic agents

such as PE, PVC and PP. Plastic manufacturers could use both coated and uncoated calcite.

• It contributes to pigment saving thanks to its high whiteness.

• Viscosity of the product decreases when coated calcite is used. Thus, dispersion is much easier and

the production efficiency is increased.

• Usage of coated calcite positively effects surface brightness and smoothness.

• As it is a coating material with low oil absorption feature, it decreases the usage of plastic agents

and optimizes product costs.

• It enables the product to be resistant against environment conditions.

• It does not contain heavy metals. Thus, reducing the machine and screw wear-out.

• It provides protection against high temperature, as it possesses a reinforcing effect.

Pipes

Calcite is used generally by pipe manufacturers that produce them with PE, PVC and PP plastics.

2 types of calcite; coated and uncoated, could be used accordingly to the manufacturer's machine

type and preference.

• The machine efficiency increases as calcite is produced in a stable fineness.

• Positively effects production costs by reducing the usage of P, PVC and PP.

•Coated calcite positively effects the surface smoothness of the pipes.

Construction Chemicals

Calcite is an important and high quality filling material used in many fields of the construction

chemicals industry such as for grouting, mineral stuff and tiling adhesive because it can be

produced in different physical characteristics and thus it can gain different densities.

• Calcite optimizes costs thanks to its low oil absorption feature. Thus, increasing the

competition power of the manufacturer firm.

• Increases the grip of the product and enables manufacturing stronger adhesives.

• Desication of the joint is delayed and the pot life of the product is extended.

• It is used as fine filling in facade mineral plaster mortars.

Paper

Calcite is used as coating and filling pigment in paper industry. It is an important industrial

mineral which is used especially in bottom and top coating of glossy paper pulps.

• Thanks to it high whiteness, it positively effects the whiteness of the paper and enables the

product to protect its whiteness for a long time. Calcite also delays the yellowing of the paper.

• By reducing the usage of expensive raw materials such as kaolin, optical brighteners and

cellulose which are used in paper sector, optimizes production costs.

• As the product is manufactured in stable fineness, positively effects the production process.

• Shows high dispersion and low wear-out effects.

• Thanks to its oil absorption and high grip, enables improved ink absorption on targeted

direction and increases print quality.

Agriculture

Thanks to its high absorption feature, calcite is applied as an additive to the soil to get healthier

products from acid soils. Thus, the lives of the organisms in these soils are ameliorated. It also

feeds the plants. It is also used as fertilizers in in lieu of Ca salts that are lost in the soil.

As calcium is essential for the bone, teeth ande egg development of the animels, calcite is an

important filling material in forages. 40% of calcite is calcium, which makes it a rich food source.

Calcite does not have any negative effects on the animals health as it does not contain heavy

metals. Calcite rate on forages should be 92%. It is used as a vitamin additive.

Medical Use

Calcite is commonly used in gastric pills as antacids. The absorption feature of calcite plays are

role in neutralizing the excess acid without creating side effects.

Cleaning Products

Calcite is used as a filling material in detergent production thanks to its high bleaching feature.

Depending on the detergent type (liquid and rubbing detergent), calcite is used as a filling

material in different thicknesses. It increases the contact rating of the detergent to the stained

surface. It decreases the costs with its filling material feature. As calcite possesses high

bleaching power, it positively effects the whiteness of the detergent. Provides cost saving by

reducing the number of additional agents that provide whiteness. It increases the UV

resistance of the detergent with its high whiteness and low yellowness features.